Quality is the bench-mark of Resinex people.

All our customers, from the small fishing farm to the big Oil&Gas company, use our products as a crucial point of their operations at sea, and that means that our products have to perform at their best for all life time.

Resinex Quality System is certified by Lloyd’s Register Quality Assurance following ISO 9001 standards.

We are member of Iala Aism and all our navigational aids products are designed following their recommendations.

We are also an Aramco Approved Manufacturer.

Each job follows a proper testing and control plan and a Resinex Certificate of Conformity is issued for each job.

A Third Part Inspection (TPI) and Design Approval from a TPA can be specifically requested.

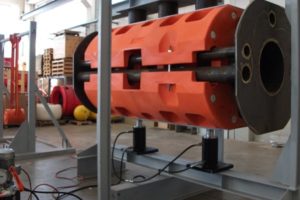

Here follow the tests that Resinex can perform at Resinex Marine Research Centre of Adro:

Hydrostatic pressure test

Fit-up test

Tension test

Buoyancy test

Impact test

Floating stability test

Torbiato Plant

Fastening removal test

Static load test

Floating stability test

On lake

Other tests are performed in outsourcing:

Liquid penetrate inspection

Magnetic particle inspection

Proof load test on steel parts

In reference to the marine lanterns by Resinex-CoSeMa, the following tests were conducted at the certification institute “Istituto Giordano” in Rimini:

Photometric and Colorimetric test

Electromagnetic compatibility

Degree of protection IP68