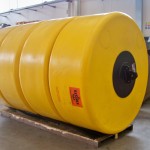

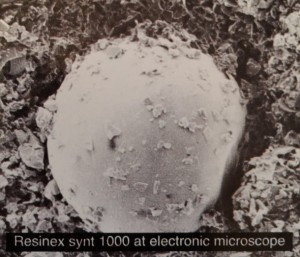

High resistance up to 11.000 metres of depth

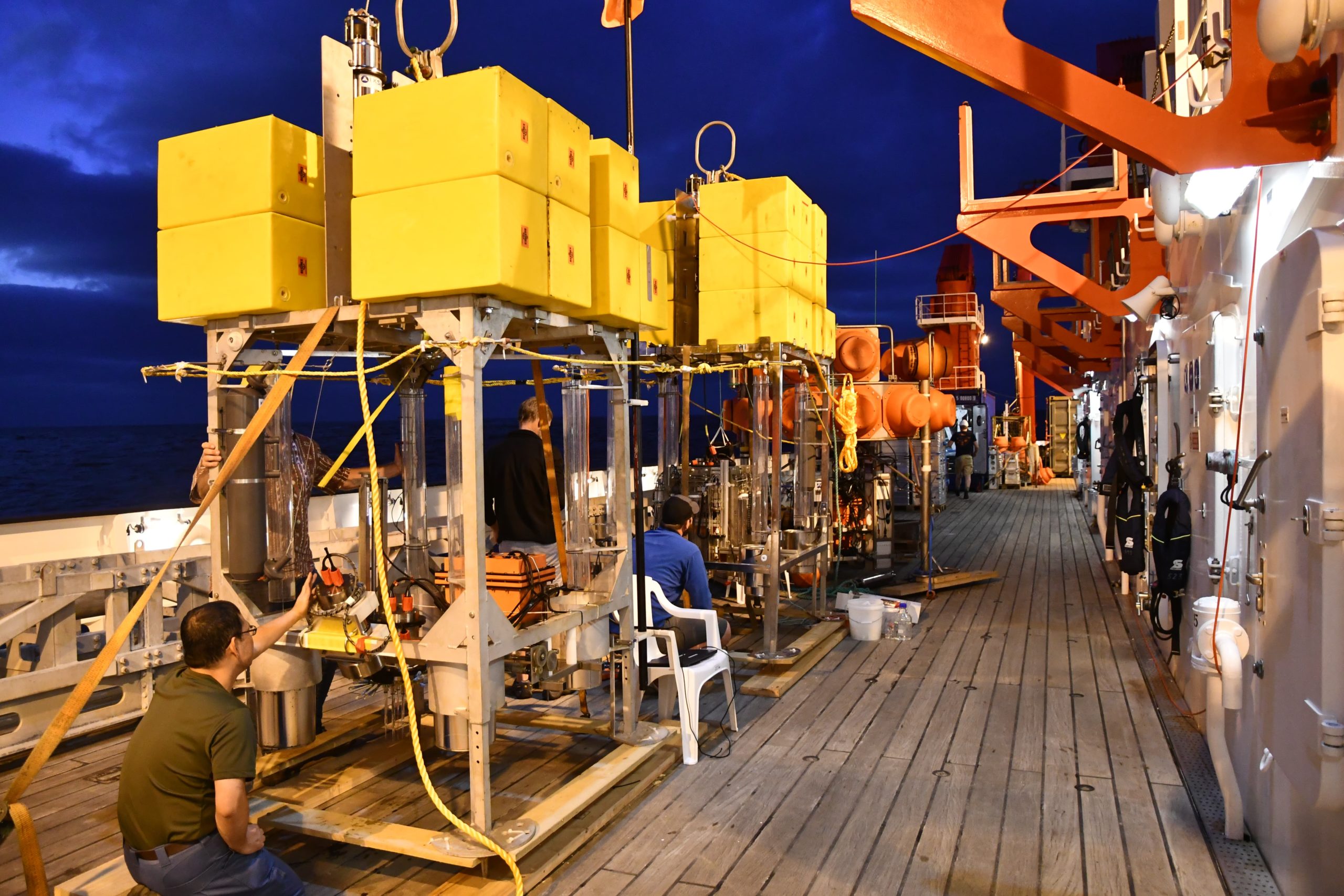

Resinex started manufacturing syntactic foam buoys in the early 1990s: after years of research and experimentations, it succeeded in creating the perfect compound suitable for floats that have to reach the deepest areas of the oceans. The specific composition of Resinex syntactic foam allows the underwater use up to 11.000 metres of depth, where a high resistance to pressure and to different external factors are necessary. The key points are a very high strength of the material and a zero water absorption rate. The excellent performance of Resinex syntactic foam modules is always confirmed by the routine quality tests carried out at Resinex Marine Research Centre in Adro (Brescia). The quality tests are essential, as Resinex always looks for improvement and product refinement. Another key point is the excellent versatility: Resinex can customize the syntactic floats according to the specific application and the depth of positioning. Syntactic foam buoys are mainly requested in the Oil & Gas and the Scientific Research sectors, where Resinex floats are used for pipeline installation, anchoring, medium and long-term positioning of submarine structures at different depths. After the first medium-small projects in the 1990s and early 2000s, with companies such as Sonsub (Eni Group) and Sonardyne, Resinex acquired the necessary experience to deal with major projects all over the world. Until today, in the Oil & Gas sector, the application water depth usually varies from 500 to 5.000 metres.

Oil & Gas: an overview

Over the last 25 years, Resinex has been supplying syntactic foam modules for Oil & Gas companies operating in the main oil fields all around the world. As for South America, one of the most relevant projects which Resinex took part in was the Frade Field Project (Chevron), when it supplied SBM Offshore with support floats in the Brazilian waters. Also the Offshore Supply Ships Up Coral and Up Pearl were furnished with installation subsurface buoys in Brazil. Resinex also participated in different projects in the Gulf of Mexico, firstly supplying the Texan company Helix with deep-water floats for the Phoenix Oilfield (ERT), and then Saipem America for the Jack St. Malo Project (Chevron), the Big Foot Project (Enbridge) and the Keathley Canyon Project (Williams DPS). Moreover, for the assembly of Scarabeo 9 Vessel, the Saipem ultra-deepwater semi-submersible drilling rig, Resinex was requested to manufacture hundreds of riser shims for 3.700 m depth, then shipped and assembled in Cuba.

- Frade Field Project

- Phoenix Project

- Jack St. Malo Project

- Scarabeo 9 Vessel

Resinex took part in the first construction of the Saipem 12000 Vessel too, in South Korea, where other riser shims for 3.700 m depth were required in order to equip the steel pipes used for oil drilling. As for China, Resinex produced buoyancy modules for the Liwan Project (Husky Oil China) and the Panyu Project, with CNOOC as main partner; few years later other syntactic foam modules were supplied to Tianjin Yada, with COOEC as final customer. COOEC has been recently supplied with spherical buoys for the Lingshui 17-2 Gas Field, too. Through the years, the EPCI company McDermott often required Resinex syntactic buoys for installations all around the world, in Malaysia, Indonesia and Australia particularly. Concerning Malaysia, McDermott required deep-water floats for the the Siakap North-Petai Project, with Murphy Oil as main operator. McDermott involved Resinex also in the Ichthys Project in Australia, whose field is owned by Inpex. Among the other relevant projects, we also find the R3454 Project for McDermott Indonesia. Fendercare, over the years, requested different kind of Resinex syntactic floats in Southeast Asia as well.

- Saipem 12000 Vessel

- Liwan Project

- Underwater and Ultra Deep Water Buoys and Floats Lingshui 17-2 Gas Field

- Siakap North-Petai Project

Related to the African area, Resinex focused mainly on Angola, Nigeria and Egypt. In Angola, Technip was supplied with floats for the Deep Pioneer Vessel and the Pazflor Field, owned by Total E&P Angola. Saipem requested buoyancy modules for the Kizomba Satellites Project, with Esso Angola as main end user. Also Fendercare ordered numerous deep-water floats for the GirRI Surf 2 Field, with Total E&P Angola as owner and Technip as main contractor. In Port Harcourt, Nigeria, Saipem requested syntactic buoys for the Egina Project, with Total Upstream as end user, and for the Usan Deepwater Project where Total E&P Nigeria was thefinal customer. One of the most recent projects in which Resinex was involved is the one concerning the Eni’s Zohr Field in Egypt, that represents the largest natural gas reserve in the Mediterranean Sea,when Saipem asked for numerous buoyancy modules and riser buoyancy modules.

- Deep Pioneer Vessel

- Kizomba Satellites Project

- Egina Project

- Zohr Project

Resinex is proud of having participated to the main Oil & Gas projects all around the world, consolidating year after year the partnership with the principal Oil Companies and Engineering Contractors.