The project is of colossal dimensions and long term. It is being carried out, on behalf of Aramco, by Snamprogetti Saudi Arabia and the consortium Star (Saipem, Taqa, Al-Rushaid).

The project is of colossal dimensions and long term. It is being carried out, on behalf of Aramco, by Snamprogetti Saudi Arabia and the consortium Star (Saipem, Taqa, Al-Rushaid).

It foresees the construction and installation of 27 offshore platforms for the extraction of oil and gas at sea including the positioning of conducts and cables. This is the first time such an undertaking of this kind and size is being carried out on the Saudi Arabian coast.

The initial agreement has a duration of seven years and foresees a renewal option. The work is taking place at a site of 300 thousand metres at the port of King Abdulaziz at Dammam with an access to deep water. It has about 900 workers and an initial production capacity of 14 thousand tonnes of steel per annum. It is here that the construction of the platforms has already begun and will be launched in the next few years.

In the next four years the positioning of at least 14 platforms is foreseen with 80 kilometres of pipeline and related cables. A project of this size and investment naturally demands the maximum quality of all the components including those collateral.

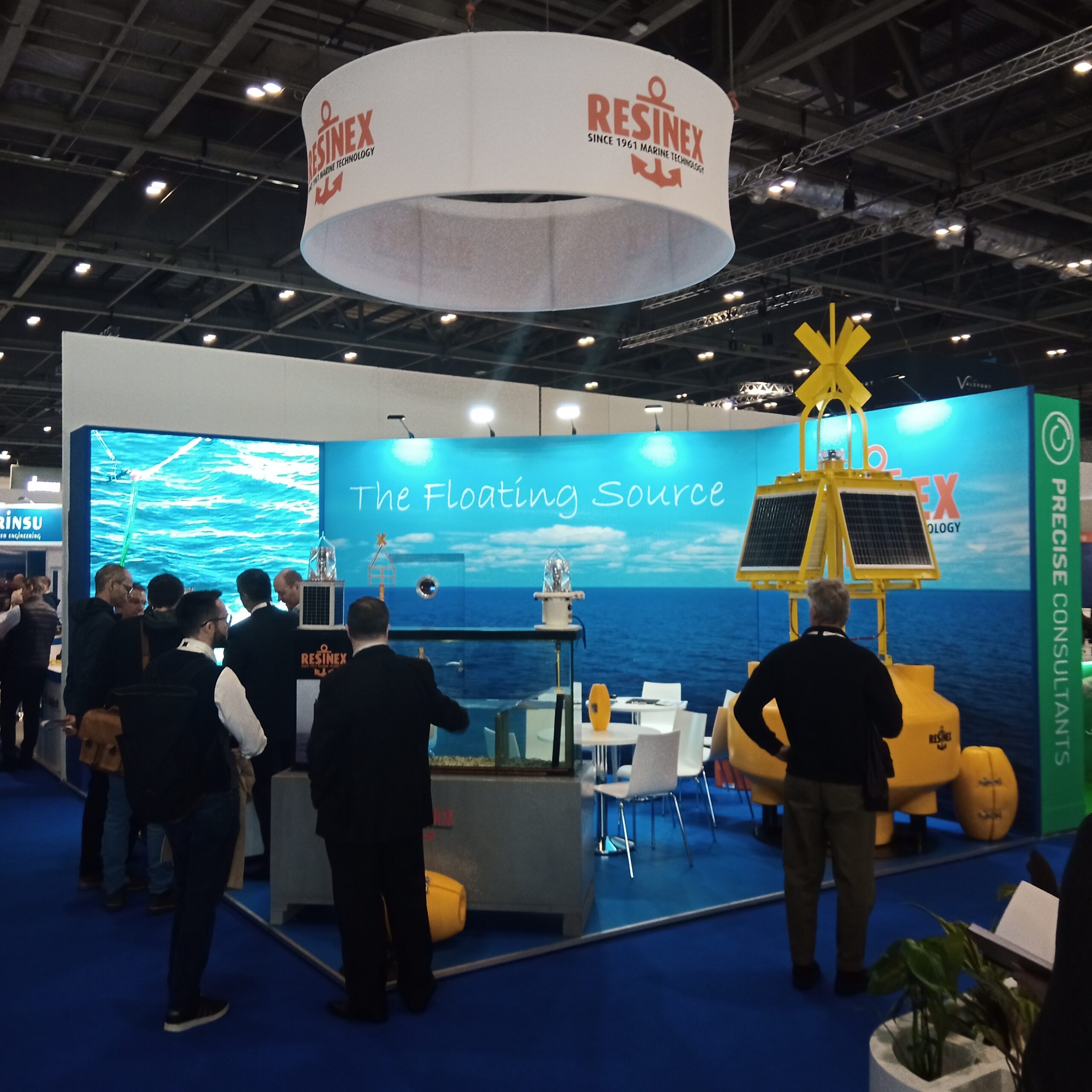

As the positioning of the opera draws closer, it is inevitable that, regarding the floating components, the project team should turn to Resinex. In order to give support to the transport, positioning and placing of the platforms, an order for 600 Resinex support buoys, model E8x1050 with a net buoyancy of 500 kilograms, arrived from Saudi Arabia.

Also for the same project, 39 damage prevention buoys in elastomer of the 4500 L type with a net buoyancy of 4,5 tonnes were ordered. All the buoys supplied for this project have been fitted with a radio frequency detector, a type of identity card in order to know the characteristics of the buoy from a distance.